“Floating Pneumatic Rubber Fenders work as a shock absorber between two ships or between vessels and berthing harbors, wharfs, or oil platforms etc. when they come alongaside each other. They float on water just like foam filled fenders which is made of synthetic-tire-cord rubber sheet with air compressed inside. Note: The floating pneumatic rubber fenders have sometimes been colloquially referred to as “Yokohama Fenders” or “Yokohama type fenders” – ISO 17357-1:2014 Ships and marine technology — High-pressure floating pneumatic rubber fenders”.

ADVANTAGE AND CONSTRUCTION FEATURES

Advantage Features: floating pneumatic rubber fenders can be easily handled and installed with guy-rope or guy-chain due to its light weight. It can resist the shearing force and maintain energy absorption level under inclined compressionup to 15 degrees. Meanwhile, provide the low and comparatively even hull pressure.

Construction Features: pneumatic rubber fenders is constructed of inner rubber layer, reinforced synthetic tire cord rubber layers, outer rubber layers. Inner rubber layer is made of pure rubber to seal pressurized air inside. Synthetic tire cord rubber layers are type middle reinforced synthetic tire cord layers with rubber dipped. Outer rubber layer is much more thicker than inner layer that is the coating and skin of whole pneumatic rubber fender.

TEST AND INSPECTION

- Acceptance testing and inspection for purchased Commercial Floating Pneumatic Rubber Fenders shall be based on the tests and inspections indicated below:

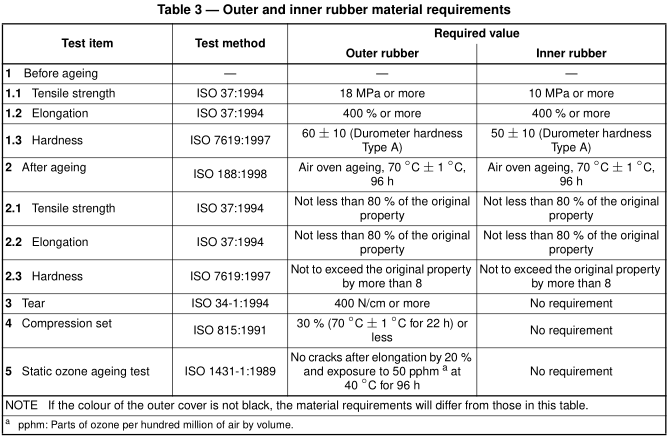

- > Material test of rubber, both inner and outer rubber layers for pneumatic rubber fenders cto be tested should be in accordance with the Physical properties of inner and outer rubber required by ISO 17357:2014

- > Dimensional inspection — shall be inspected at the initial internal pressure. Tolerance: +10%, -5%.

- > Air-leakage test — shall be conducted at initial pressure for more than 30 min

- > Hydrostatic-pressure test — shall be performed for 10 min at the hydrostatic pressure shown in “test pressure at 0% deflection”. Maximum temporary elongation: 10%

SPECIFICATION AND PERFORMANCE

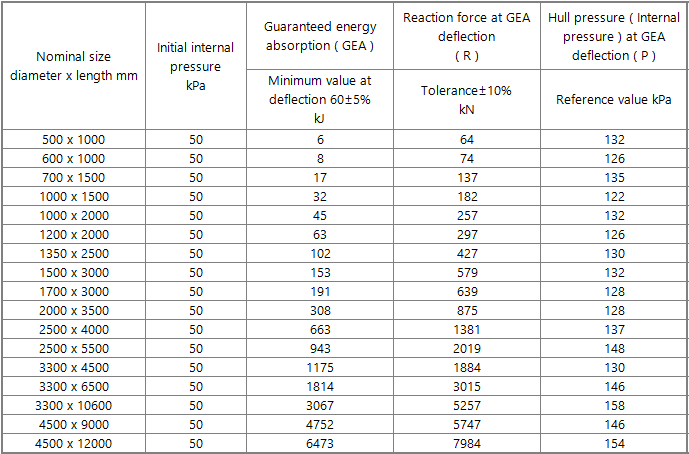

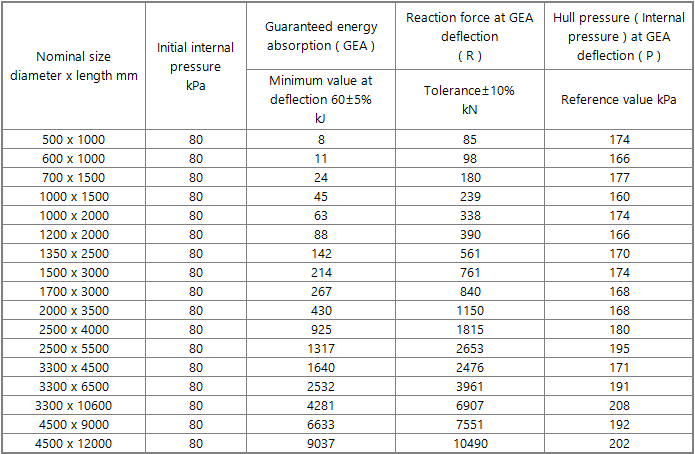

The performance of floating pneumatic rubber fenders shall be specified in terms of Guaranteed Energy Absorption (GEA), Reaction Force at GEA deflection, and Hull Pressure at GEA deflection.

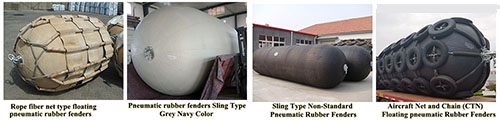

FENDER TYPES

- – Pressure Requirement

- Ronsen Yokohama type pneumatic rubber fennders are classfied in initial pressure and shapes, appearance. According to pressure requirements of ISO 17357, we produce two standard intial pressure for pneumatic rubber fenders, Pneumatic 50, initial internal pressure 50 kPa ( called P50 ) and Pneumatic 80, initial pressure 80 kPa ( called P80 ).

- – Fenders Type

- As per global clients demands, Ronsen Marine develop several type of pneumatic fenders which are listed follows including Type I, CHN Aircraft and truck net type, Type II, sling type, grey navy colored fenders, rope type fenders.