“Ronsen Marine is China leading manufacturer of heavy duty and high performance foam filled fenders, floating foam foam fenders for the marine and oil, offshore industry”

Ron-Cushion netted foam filled fender is covered by a protection chain and tire net srround the fender body to provide protection for the foam fender. Ron-Cushion foam fenders is one kind toughest fendering system for harbor, offshore, millitary use and ship-to-ship application. Ron-Cushion foam filled fenders are able to absorb 40% more energy comparing with sized pneumatic rubber fenders, with relatively reaction force than other marine fendering systems.

Advantages of Ron-Cushion Type Netted Foam Filled Fenders

Except the production chain and tire net, Ron-Cushion foam filled fenders are constructed with closed-cell, energy absorbing resilient foam, nylon filament reinforced, tough polyurethane skin. This Construction offers a number of important features and advantages.

-

Tough, nylon filament reinforced polyurethane skin

-

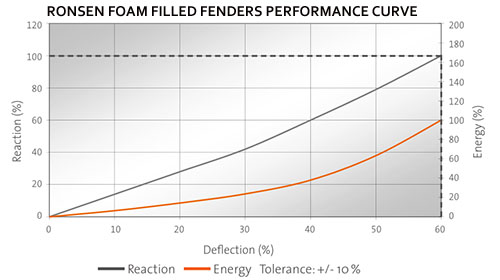

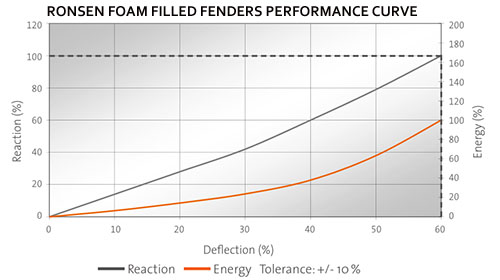

High energy absorption and low reaction force

-

Closed cell foam will not absorb water

-

Will not fail even if skin is punctured

-

Protection for rough surface

-

Adjust to water level

-

Low maintenance

-

Easy installation

-

Large standoff distance

-

Custom colors available

-

Hot-dipped galvanized swivel and fittings

Construction of Ron-Cushion Netted Foam Fenders

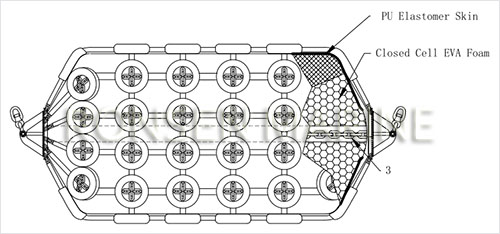

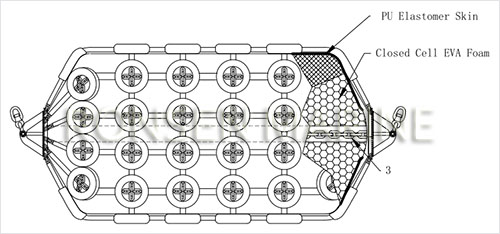

Ron-Cushion foam fenders are fabricated with closed-cell resilient foam, with tough polyurethane elastomer skin, reinforced with nylon filament, and protection chain and tire net.

A. Ron-Cushion foam filled fenders also are filled with highest quality resilient closed-cell foam. This specific foam can provide high energy absorption with relatively low reaction force. Even the skin was punctured. It also is unsinkable without absorbing water. With our unique laminating process, each foam core is integrity. The foam can not be ruptured when comprssed.

B. Ron-Cushion foam fenders’ skin is constructed of polyurethane elastomer which is reinforced with nylon filament. The polyurethane skin is unique elastomer specifically for foam fender applications. More thicker filaments and elastomer are applied to both ends to better resist the defection and shearing force.

C.Comprising through central steel tube and external load distribution flanges at each end. All end fitting are hot-dip-galvanized. Without the through pipe, all longitudinal chains are joined to Clevis eyes at both ends of the fender.

D. Ron-Cushion foam filled fenders incorporate chain and tire net. The chain and tire net design uses heavy duty hot-dipped galvanized chain, fitted with heavy ties at the net intersections. This chain and tire net carry the tensile load, minmizes stress in the fender skin.

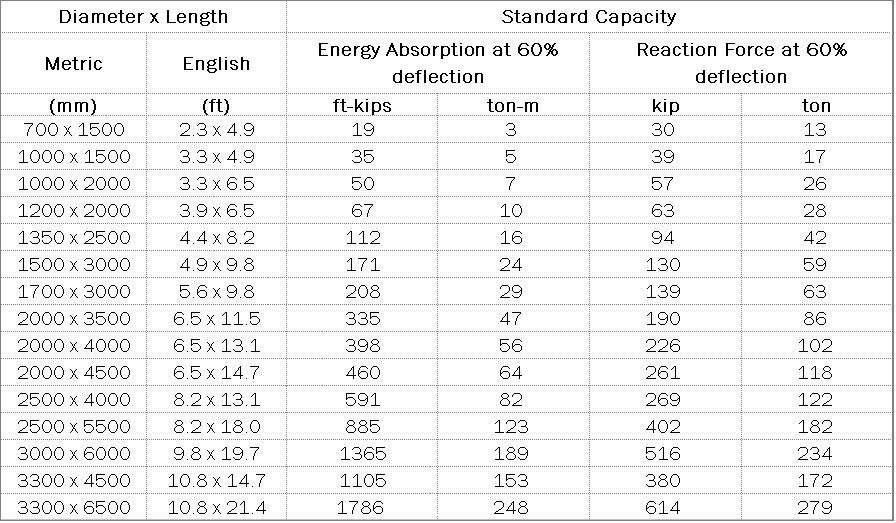

Cushion Netted Foam Filled Fenders Dimension Sheet

Ron-Cushion Type Netted Foam Filled Fenders are normally supplied with standard capacity. Low reaction capacity, or high capacity also are available upon clients’ request.

All Ronsen Marine Foam Filled Fenders are manufactured comply with US Navy and Coast Guard specification, and PIANC Guidelines.